3D inline inspection monitoring

The JackNbox 3D Production Inspection System

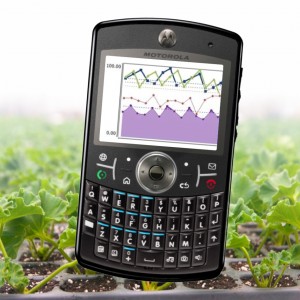

The JackNbox Production Inspection Systems have been developed to enable volume producers to trace every product from initial build to final dispatch. Automated tracing and inspection with real time SCARDA management information logging for early identification and recording of product development rates enabling early intervention within the production process. Applications include horticultural environments and assembly lines.

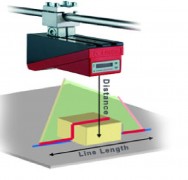

The JackNbox Line Inspection Sensor System is used whenever sizes and positions of stationary or moving objects are to be measured. An additional encoder connection permits the recording of 3D data when scanning objects to assess stages of development through measurement of height, depth and width. Rapid 3D analysis against predetermined parameters opens up a large range of application possibilities in object position and volume measurement revolutionising the production process through the provision of rapid Management Information (MI) which gives management the essential statistical analysis needed for improving production processes. Standalone and production line systems, the JackNBox Plant Inspection System can be customised to suit a large range of applications.